Sapori Di Napoli – Creating the Perfect Pasta

|

|

| Supporting Family-Owned Artisan Producers of Hard-to-Find Ingredients since 1999 |

|

Three classic “hand-made-based” shapes from Sapori di Napoli. |

|

Order your Reed Avocados Today |

Peter and Bonnie are hard at work harvesting their luscious Reed Avocados. Get your daily avocado fix today. Before you know it, the season will be over. Don’t miss it!

Peter and Bonnie are hard at work harvesting their luscious Reed Avocados. Get your daily avocado fix today. Before you know it, the season will be over. Don’t miss it!

|

|

Newsletter Contest Continued... |

Last week we received many good guesses, and at least one was correct. For everyone else, here’s your second chance. Correctly identify what type of tree this is, (Recognize the leaves? It is the same tree as last week) and automatically be entered to win a half pound of its majestic crop. From all the correct entries we will randomly pick a winner. We will select and notify the winner by email by October 1st, 2010. Send us an email with your best guess to enter to win! Please place the words, “newsletter contest,” in the subject line.

|

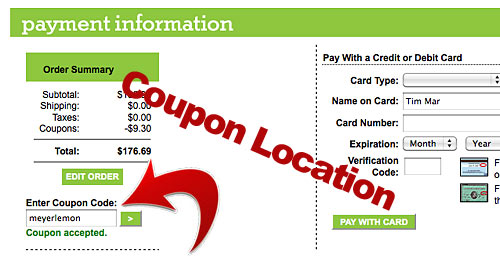

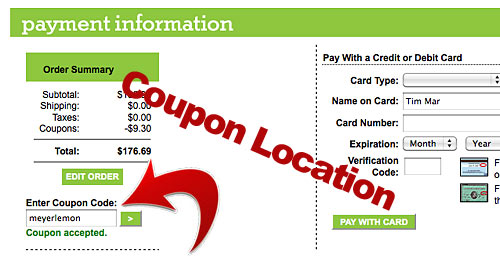

Newsletter Subscriber Discount Code

|

Enter this code in the "coupon code" box during checkout (see below). Our thanks for subscribing! (Valid through Tuesday, September 28, 2010. Discount not valid on fresh/perishable items or already discounted products.)

|

Do you know someone who would enjoy this newsletter?

Forward it to a friend by clicking here. |

You've received this email because you have purchased from us or subscribed. We respect your privacy online, and will never share your email address.

|

|

Peter and Bonnie are hard at work harvesting their luscious Reed Avocados. Get your daily avocado fix today. Before you know it, the season will be over. Don’t miss it!

Peter and Bonnie are hard at work harvesting their luscious Reed Avocados. Get your daily avocado fix today. Before you know it, the season will be over. Don’t miss it!